Buy Dry Lube | cdn11.bigcommerce.com

Though there are many lubricants available to help reduce friction between moving metal parts of machinery. Today it is the dry lubricants that are much sought after. Their superior lubrication qualities plus many other properties make them suitable for maintaining heavy-duty machines used in various industries today. Regular application of any dry lubricant ensures that a machine’s performance is strong, constant and helps to prevent expensive repair costs.

Buy Dry Lube To Bring Down Machine Maintenance Costs Significantly

Why is using a dry lube so important? One of the main reasons why it has come to extensive use today is due to the fact that it is capable of staying in the right condition, even under extremes of temperature and also pressure. In fact, it is what’s needed when oil is unable to carry out its lubrication purposes in heavy duty machinery or engines which are subject to extremely high temperature and pressure. Buy Dry Lube to use it instead of oil for lubrication purposes. dry lubricants have the ability to work effectively and give desired results, time and again even if the environmental conditions are extreme.

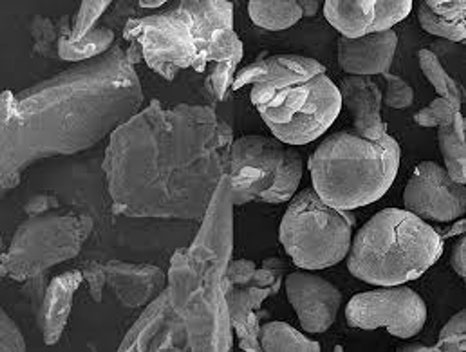

A dry lube is the right choice for lubrication when you want to protect metal parts or components from wear out and extreme repair issues caused by frictional movement. Due to the fact that they have a low coefficient of friction they will assist in eliminating the friction that arises between them when they move. As a result, they move smoothly when the machine is in operation, which reduces the energy or power consumed in operations. Furthermore, they work faster hence the machine’s output is better. Regular use of dry lubricants such as tungsten disulfide, molybdenum, disulfide etc will make the task of carrying out maintenance easy and also less expensive.

When you compare a dry lubricant with other lubricants, you will find them to provide desired results better. Today’s; industrial machines are very sophisticated and advanced technology has brought about situations where such machines work under extreme pressure, temperature and humidity. There can also be systems working with vacuum technology. All such advanced systems and more need more than a simple liquid lubricant that can provide only essential lubrication under general environmental conditions. They need a tough dry lubricant such as WS2 else MoS2 to fulfill their lubricant needs. A dry lubricant has the power to remain stable and stay in place in matter what the circumstance surrounding it.