Tungsten Disulfide | cdn11.bigcommerce.com

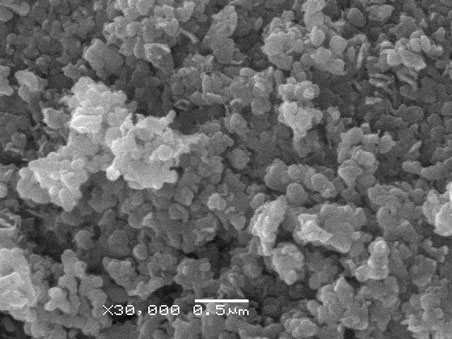

The solution of tungsten Disulfide may turn out to be the right one that can be used. It is available in the form of a coating that can be applied on the surface base where it may not be easy in reaching out. This may formulate a form of bonding with the aid of the substrates and develops a type of coating film. With the other components, tungsten disulfide is known to be chemically inert.

The spray is expected to provide superior lubrication temperature that ensures things are done in a proper way. One of the features of the spray is an extensive load-bearing trait with a host of other specialities. The spray is bound to be less degree of lead or fluorocarbons and you need to admit that the spray is unique on all counts.

Functions and right application of Tungsten Disulfide spray

The use of tungsten disulfide spray tends to take place at a basic level and is part of the power transmission components. For the viable operation of the machinery components along with precision gear, it is important. In reality, the plastic moulds as you would come across the extrusion dying for the betterment of things. The main use of the spray is in the defence or aerospace domain which may turn out to be useful when it comes to the machine parts.

A few of the things are visible that are going to function normally with the application of the spray. Their main use would be for rollers, spindles, shafts and seals. It is mainly used for robotics and a host of other sporting items. For cutting tools you can use tungsten disulfide spray and even it can be used for cutting tools, punches or other dies. The spray when it is applied properly may lead to a smooth operation of the ammunition parts along with the bullets.

There are bound to be the spray cans as you may term them to be dangerous goods since the shipment is being made by air. Since the spray turns out to be dangerous it would be better if you keep it away from the reach of the children. The use of the spray has to be undertaken with a degree of safety and if you are not careful health hazards may occur.

Coming to coating of tungsten disulfide turns out to be a durable form of coating and you need not maintain it for a year or so. Talc or glass-filled resins which are 30 % or more is bound to reduce the durability of the life of the coating due to the abrasive nature associated with the same. This will be beneficial in the long run.