When choosing a plastic material for items, polycarbonate is usually preferred over acrylic since it is stronger and more resilient. Not only is polycarbonate incredibly lightweight, but it is also almost indestructible and provides remarkable protection against many forms of damage.

Whatever project you're using polycarbonate for, the polycarbonate sheet suppliers in UAE can provide custom-made sheets that are made to exact specifications. If you're experiencing problems choosing between polycarbonate and acrylic plastic sheets, this information could be useful. We go over polycarbonate sheets, their common uses, and the main differences between acrylic and polycarbonate.

How come polycarbonate is used?

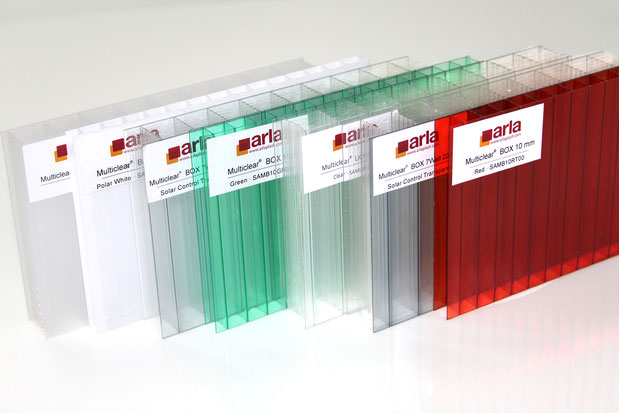

Polycarbonate is a thermoplastic material that is transparent and strong, resistant to impact and moisture damage because to its low moisture absorption and toughness. They also demonstrate excellent stability, resistance to heat, flames, and chemicals.

Working with polycarbonate sheets is easy because it's a simple material to cut and connect using bolts, nuts, and screws. It is easy to make and scale polycarbonate using cutting and thermoforming procedures.

Reusing or injection moulding polycarbonate is easy since it dissolves at 155 Celsius temperatures and may be repeatedly cooled and heated without suffering severe degradation.

Polycarbonate's strength and resilience make it the perfect material for situations where safety and security are critical considerations.

Which Uses Are There for Polycarbonate Sheets?

Due to its weather and UV resistance, polycarbonate sheets are ideal for usage in both indoor and outdoor settings, as well as in industrial and do-it-yourself projects. Manufacturers commonly employ polycarbonate plastic for a number of purposes. For example, polycarbonate is widely utilised in the production of laptops, CDs, DVDs, and mobile phones.

Because our premium polycarbonate sheeting is almost indestructible and has an extended lifespan, it is perfect for outdoor applications and the roofing industry.

- Under umbrella roofs

- Roofs of conservatories

- The construction process

- Components used in automobiles and aeroplanes

- Glazing

- Building covers for greenhouses

How do polycarbonate sheets fit together?

If you want to employ polycarbonate sheets for a future project, you may be wondering how to fit them. Although we recommend using sealing compounds, you can puncture the material if you wish, but be careful not to penetrate too close to the edges or cause cracks or other damage. If you do decide to pierce the sheet, make sure it is tightly held from below.

Cutting through polycarbonate sheets while they are in situ should only be done with a hand saw or a circular saw fitted with tiny teeth. To prevent dust, moisture, or vermin from entering the material, sealant should be applied to any visible crevices. Please be advised that polycarbonate sheet suppliers in the UAE also provide roofing accessories for multiwall.